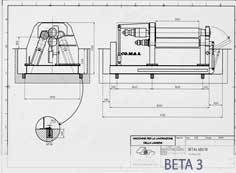

3 ROLL DOUBLE PINCH PLATE ROLLS

BETA 3 (16 models )

All Hydraulic

Super Heavy Duty

Rated at 50,000 psi/ 350 N/mm² material Yield Strength

14 to 61mm / 0.551" to 2.677" thickness

2100 to 4100mm / 82" to 161" width

Solenoid valve controls

|

|

The Beta 3 is designed to roll steel above 25mm / 1.000" thick with yield strength of 350N/mm² / 50,000 psi to 1.4 the top roll

diameter of the machine. COMAL believes that to assure positive results of the function and durability of the roll when it is

purchased with the intention of rolling such thick materials day in and day out, meaning 16+ hours shifts, the slide and block

system is the answer. COMAL accepts the fact that an orbital path system for the bending rolls' movement with linkage style

mechanisms may be used (as in our Kappa design). The fact remains that line contact bearings are inferior, for wear

and load carrying capacity, when compared with that of large surface area contact bearings.

Comal is also ready to provide our customers with a choice. If you request, we will offer you a Kappa 3 with the orbital motion system having the same

capacities of the Beta 3 machines, at the lower price.

Cone bending on these machines will require you to reduce the machine capacity by 25% on thickness and length.

For more information concerning cone bending contact our sales engineers.

Machine Standard Features:

· Frame built of laser cut high strength steel, welded, stress relieved and sand blasted.

· All UL listed GE electrical components or equivalent installed in a UL listed NEMA 12 equivalent electrical cabinet with master breaker

· Hardened rolls to HRC 54-56

· Hydraulic unit by Rexroth and valves by Aron

· Three rolls are powered individually with hydraulic motor/ epicylic gear reducer sets.

· Hydraulic drop-end

· Automatic rolls paralellism by a micro processor

· Tilting of the bending rolls by means of proportional valves and PLC

· Top roll hydraulic balancing system

· Bending rolls assembled on heavy duty SKF bearings

· Centralized lubrication by means of a hand pump

· Cone bending device

· Tilting of bending roll directly from controls console

· Separate controls console on wheels

· Four digital readouts (two for each bending roll)

· Safety devices and operating manual according to CE norms

Optional Features and Equipment:

· Polished, ground or chrome plated rolls

· Variable speed

· Universal section bending tools

· Hydraulic squaring back stop

· Vertical hydraulic support max. Ø 2500 mm/ 98” & max. weight 1600 Kg/ 3530 lbs

· Vertical hydraulic support max. Ø 3600 mm/ 141” & max. weight 2200 Kg/ 4850 lbs

· Vertical hydraulic support max. Ø 4300 mm/ 170” & max. weight 5000 Kg/ 4850 lbs

· Hydraulic side-support Max. 1500 Kg/ 3310 lbs

· Hydraulic side-support Max. 3000 Kg/ 6615 lbs

· Hydraulic side-support Max. 4200 Kg/ 9262 lbs

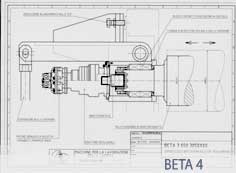

4 ROLL DOUBLE PINCH PLATE ROLLS

BETA 4 (16 models )

All Hydraulic

Super Heavy Duty

Rated at 50,000 psi/ 350 N/mm² material Yield Strength

16.5 to 88mm / 0.650" to 3.464" thickness

2100 to 4100mm / 82" to 161" width

Solenoid valve controls, NC or CNC

|

|

With brute power and built to last!

The Beta 4 is designed to roll steel above 25mm / 1.000" thick with yield strength of 350N/mm² / 50,000 psi to 1.4 the top roll diameter of the machine.

COMAL believes that to assure positive results of the function and durability of the roll when it is purchased with the intention of rolling such thick materials day in and day out, meaning 16+ hours shifts, the slide and block system is the answer. COMAL accepts the fact that an orbital path system for the bending rolls' movement with linkage style mechanisms may be used (as in our Kappa design). The fact remains that line contact bearings are inferior, for wear and load carrying capacity, when compared with that of large surface area contact bearings.

Comal is also ready to provide our customers with a choice.

If you request, we will offer you a Kappa 4 with the orbital motion system having the same capacities of the Beta 4 machines listed below, at the lower price.

Also presented are the capacities at 36,000 psi/ 250N/mm² for comparison with other suppliers' machines, which may be rated at this yield strength and 3 to 5 times the top roll diameter!

Cone bending on these machines will require you to reduce the machine capacity by 25% on thickness and length.

For more information concerning cone bending contact our sales engineers.

Machine Standard Features:

•Frame built of laser cut high strength steel, welded, stress relieved and sand blasted.

•All UL listed GE electrical components or equivalent installed in a UL listed NEMA 12 equivalent electrical cabinet with master breaker

•Hardened rolls to HRC 54-56

•Hydraulic unit by Rexroth and valves by Aron

•.Top and pinching rolls are powered individually with hydraulic motor/ epicylic gear reducer sets.

•Hydraulic drop-end

•Automatic rolls paralellism by a micro processor

•Tilting of the bending rolls by means of proportional valves and PLC

•Top roll hydraulic balancing system

•Bending rolls assembled on heavy duty SKF bearings

•Centralized lubrication by means of a hand pump

•Cone bending device

•Tilting of bending roll directly from controls console

•Separate controls console on wheels

•Four digital readouts (two for each bending roll)

•Safety devices and operating manual according to CE norms

Optional Features and Equipment:

•Polished, ground or chrome plated rolls

•Powered bending rolls each with its individual hydraulic motor/ epicyclic gear reducer

•Variable speed

•NC and CNC options

•Vertical hydraulic support max. Ø 2500 mm/ 98” & max. weight 1600 Kg/ 3530 lbs

•Vertical hydraulic support max. Ø 3600 mm/ 141” & max. weight 2200 Kg/ 4850 lbs

•Vertical hydraulic support max. Ø 4300 mm/ 170” & max. weight 5000 Kg/ 4850 lbs

•Hydraulic side-support Max. 1500 Kg/ 3310 lbs

•Hydraulic side-support Max. 3000 Kg/ 6615 lbs

•Hydraulic side-support Max. 4200 Kg/ 9262 lbs