|

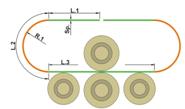

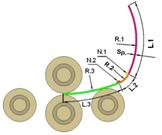

Initial Pinch Plate Rolls

|

|

|

|

Double Pinch Plate Rolls

|

|

|

High Speed Automatic Rolls

|

|

|

Hvac and Duct Manufacturing Equipment

|

|

|

Other Roll Forming

Machinery & Equipment

|

|

|

|

|

|

|

|

|

|

|

CONTROLS OPTIONS

CNC Control for: ALPHA4, KAPPA 4, BETA 4

The KVARA 2003 CNC is user friendly and has interpolation capabilities with hydraulic proportional valves so it can roll different shapes without stopping at curvature change nodes. Operator input is via sealed membrane push button keyboard. Full color display.

|

These are rolling profiles already progammed in the Kvara 2003 and all the operator needs to do is insert the parameters for the specific profile. The controls will roll a part without any further input from the controls console. A user may program any profile he/she needs and save the same which he/she may use for other similar parts by changing the parameters. The above are some of the more established shapes in the industry.

|

CNC Control for: ALPHA4, KAPPA 4, BETA 4

|

The TESEO CNC model CN4-S6 is a lesser priced control unit than the Kvara 2003. Display is black/gray and it has the auto teaching capability, without interpolation. The difference between "with interpolation" and "without interpolation" is the following: When the controls are capable of interpolation that would mean there exist hydraulic proportional valves installed, which receive data from the controller and are able to move the axes incrementally, continuously and simultaneously.

|

|

|

This results in giving the machine the capability to roll parts of complicated geometry, without stopping at every input node. This is necessary when onerolls prefinished stainless steel or aluminum, whereby there is no allowance to leave a "Stop line" on the surface of the part. A "Stop line" is imparted to the rolled part every time the rolls stop and start, which would be the case with controls lacking the interpolation feature.

|

PLC Control for: GAMMA2 and FOUR-MATIC

|

The MAPER HT072 is a two axes sequential positioner with capabilities of parts counter and hours counter, well suited to the GAMMA2 and FOUR-MATIC 2000 operations. Easy to program and operate. It can work in Manual, Semi automatic and Automatic modes.

|

|

|

It is very easily integrated with PLCs used for automatic feeding and with other auxiliary equipment, which are usually used in cases of high production on the GAMMA2 and the FOURMATIC 2000.

|

CNC Control for OMEGA

The EASY BENDER is very powerful and specific to section rolling. Automatically calculates section moduli and compensates for disparity in results. Does interpolation with proportional valves. The EASY BENDER is for the section rolling machines as is the Kvara 2003 for the plate rolling machines. It gives the user the options of "Multiple pass programming" or "Single pass programming". Its capacity for roll positioning required to bring the part to the exact parameters entered is a feature , which saves guessing, time and money.

NC Control

The LYNX NC is a three axes readout NC with Auto-Teaching programming. It can store 100 programs with 80 steps each and has one RS232 port for network communication.

|

NC Control

The TESEO CN-50 NC is also a three axes controller with two RS 232 serial ports. It is the choice of some of our customers who are already familiar with its operation. It has a color graphics display. This model is also used on the WELLE.

|

|

|